Our equipment

LPL equipment

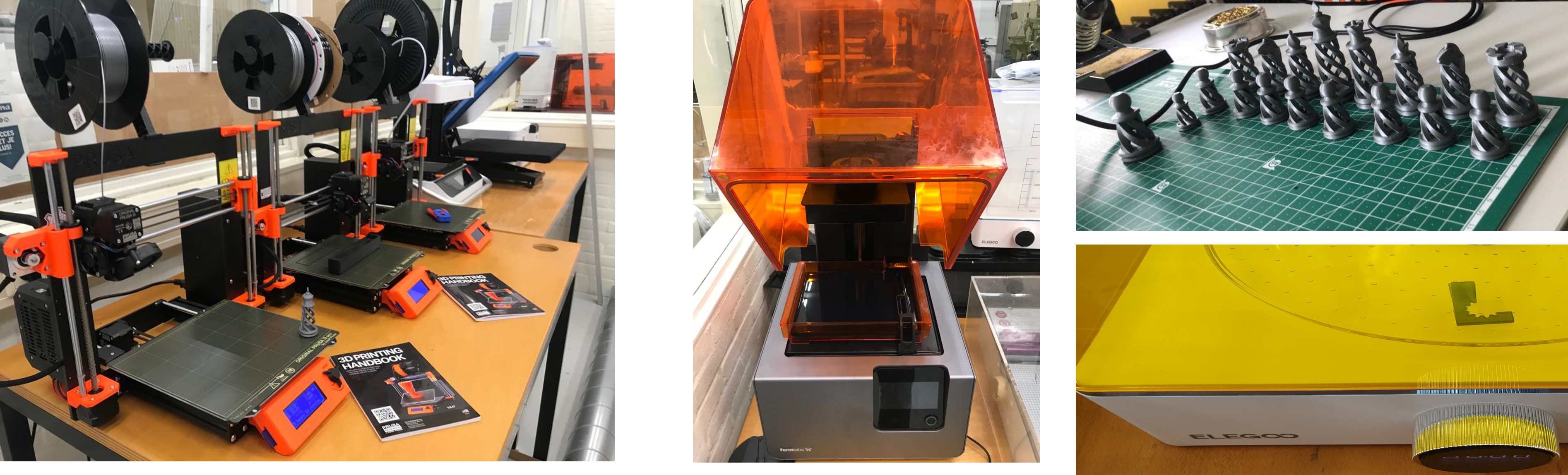

Additive fabrication

Filament printers:

Filament printers extrude molten filaments to create complex and precise 3D designs. They are useful for building custom parts in small numbers and can be expanded to a range of materials. We have a range of printers including multi-material printers and dual head printers.

Resin printers

Resin printers use a laser to harden resin polymer to create smooth and highly precise 3D designs. Their resolution is very high.

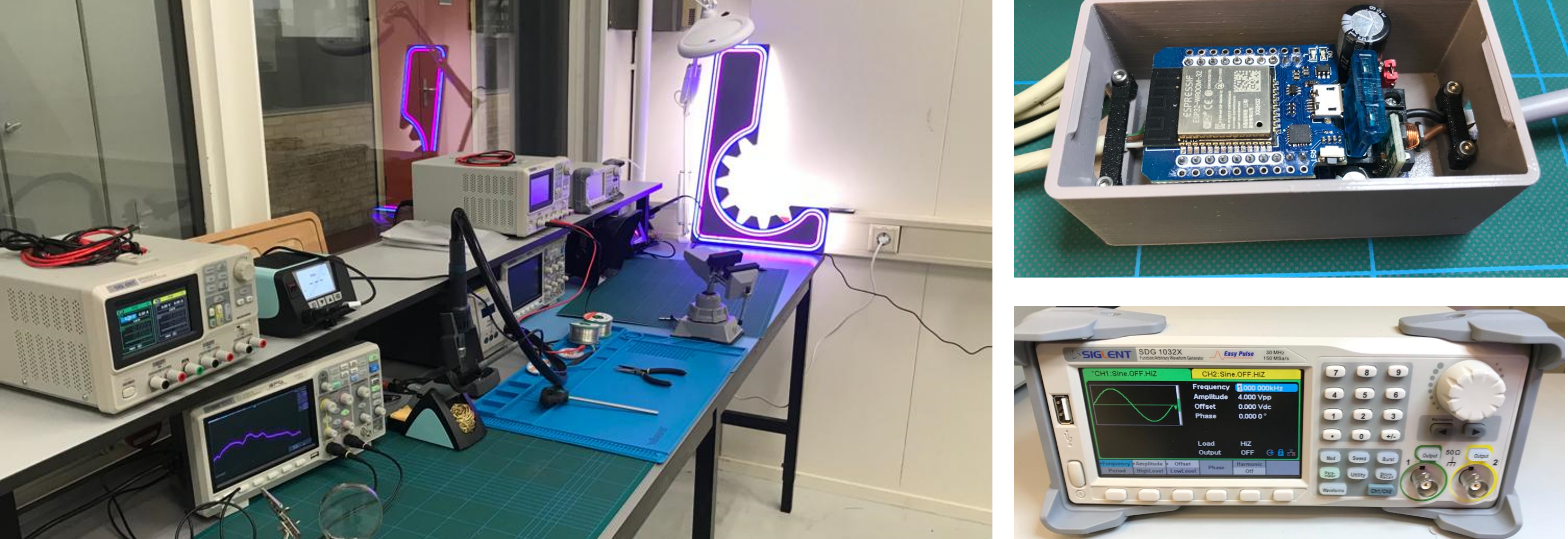

Soldering stations

Soldering stations are used to connect electronic components. Electrical components can then be tested using our power packs. We also have oscilloscopes and pulse emitters for testing a range of functions within the circuits.

Embroidery machine:

The Embroidery machine functions as a traditional embroidery machine but has the added automation function which allows it to sew complex patterns independently of its user. This can occur over an area of approximately 26 x 18 cm.

Subtractive fabrication

Laser cutter

The laser cutter is able to cut or engrave shapes on a 2D plane into materials including acrylic and wood. This is useful for creating designs on the surface of a material or cutting shapes out.

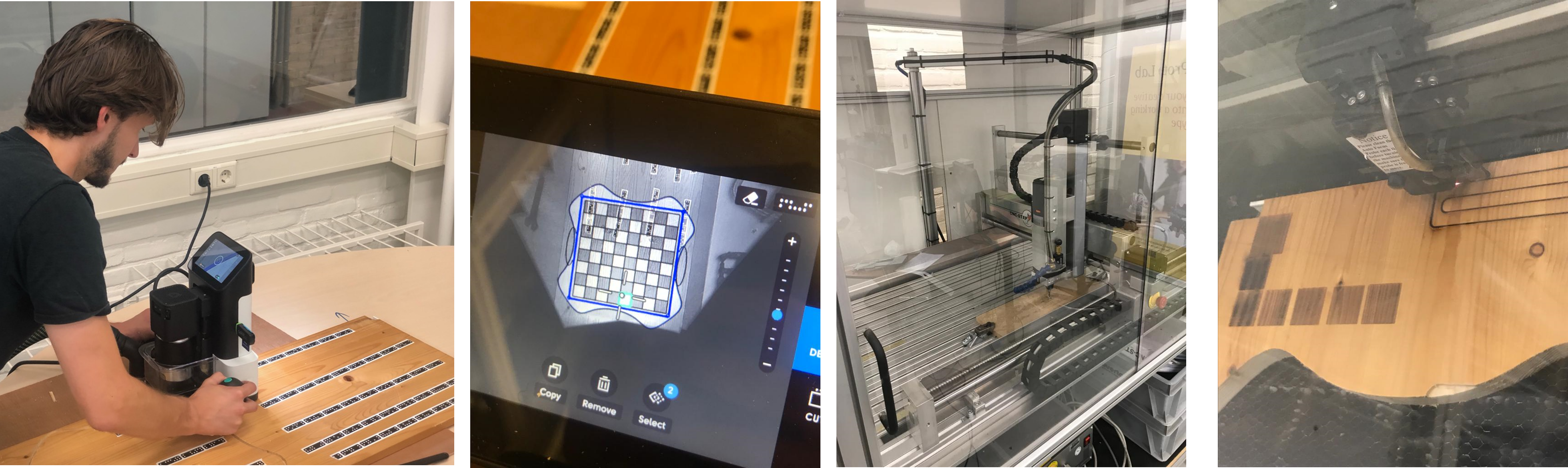

CNC router

This is able to cut shapes out of materials using a drill bit in a function close to milling. It can be used for plastics, wood or foam or materials that could be sensitive or non-reactive to a laser. It requires a high-level understanding of the programs that it uses to know where to cut.

Handheld augmented reality router

The Handheld router is a portable machine capable of cutting wood or foam. Using special markers it knows where it is placed on the surface of a material and can be guided with extremely high precision to cut very complex shapes, even by someone without experience. It is easy to use.

Cutting plotter:

The cutting plotter is able to cut out designs on thin sheets of material such as vinyl, paper or plastic sheet.

UV Lithography:

Our UV Lithography device can perform soft lithography and masking using a UV-LED light-based source.

Shaping / decorating

Vacuum former:

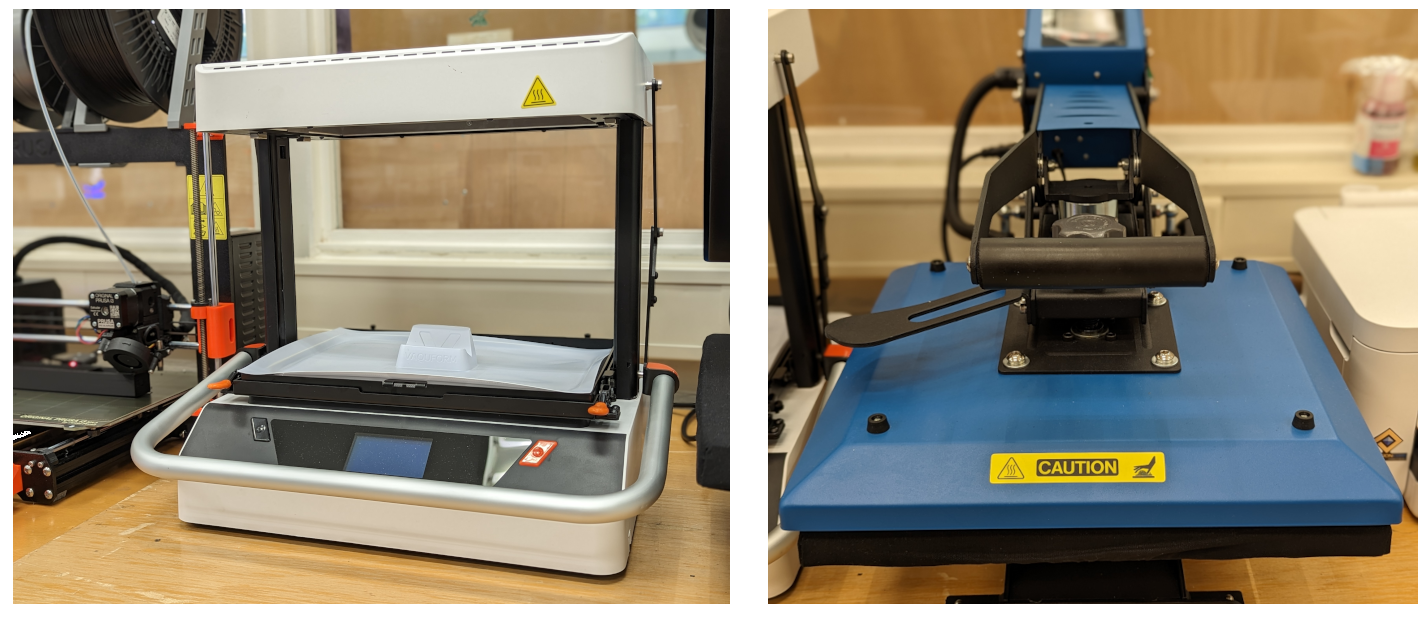

The Vacuum former can be used to create thin 3D moulds or surfaces using plastic. It is not as highly customisable as the 3D printers but is almost instant and food-safe (e.g., for custom chocolate moulds!). It is especially useful for epoxy or silicone moulding, transparent covers and inverted topologies.

Heat press:

The heat press/transfer can warm and exert forces on materials across a wide surface area. This can enable transfer from one material to another and is commonly used in textile making.

A3 Pouch laminating machine:

Laminate your design in plastic for added robustness.

Conventional equipment:

In addition to our (mostly digital) tools we also have shared use of a range of conventional fabrication tools such as saws, drills, a mill, lathe, welder and bending machines.

Note: some of this equipment requires prior experience and/or direct supervision to operate. Use of this equipment can be requested via the normal channel: the project application form.

Measurement equipment

Aside from the common calipers, rulers, spirit levels, etc. the lab also features a range of micrometers, balances and scales and other accurate measurement devices. Our 3D scanner can create digital scans of objects (~5 cm-5m) with an accuracy of up to 0.04 mm. IR camera’s and probes are available for thermal measurements.